Mission-Driven Transformation

Mission-Driven Transformation

Across our business, we are transforming with urgency to deliver the speed, agility and insights our customers need to stay ahead of rapidly-evolving threats.

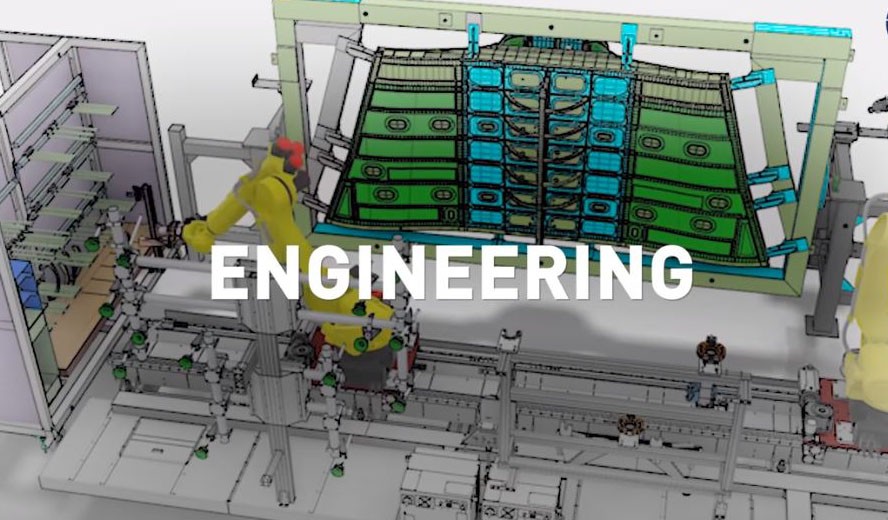

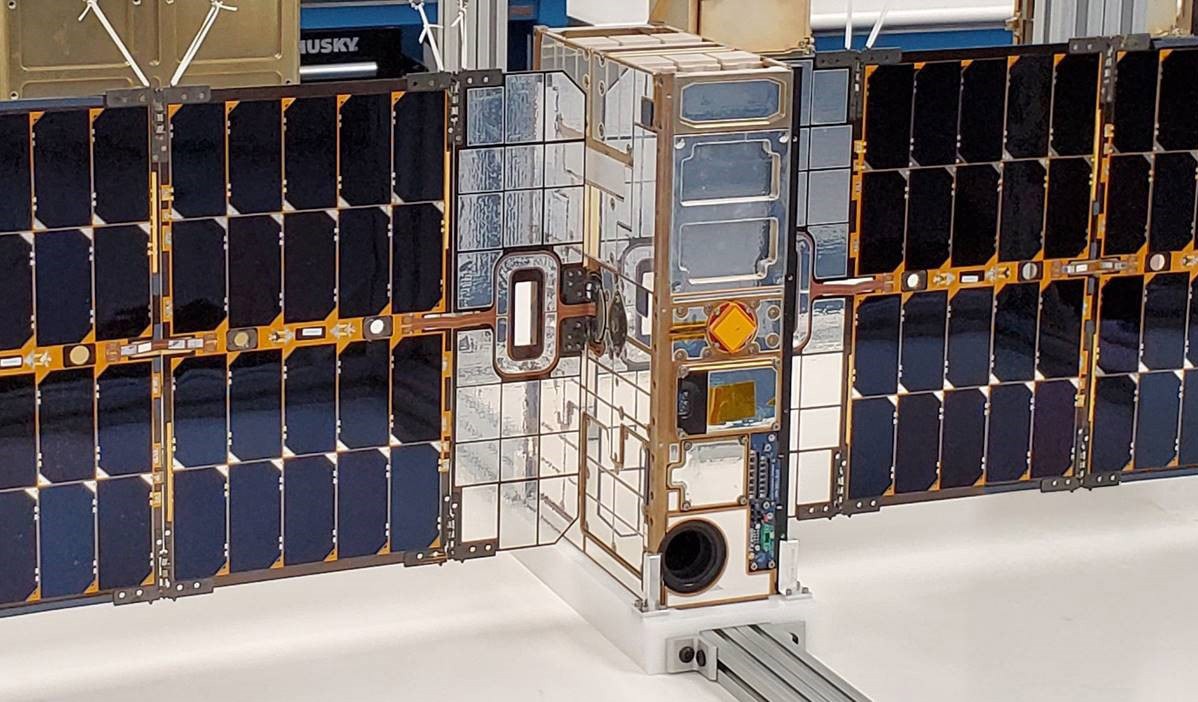

Enter 1LMX, our mission-driven business and digital transformation program. With 1LMX, we’re transforming our end-to-end business processes and systems. We’re also creating a model-based enterprise with a fully integrated digital thread throughout the design, build and sustain product lifecycle. Through new innovations and partnerships, we will accelerate 21st Century Security capabilities to support our customers’ national security missions.